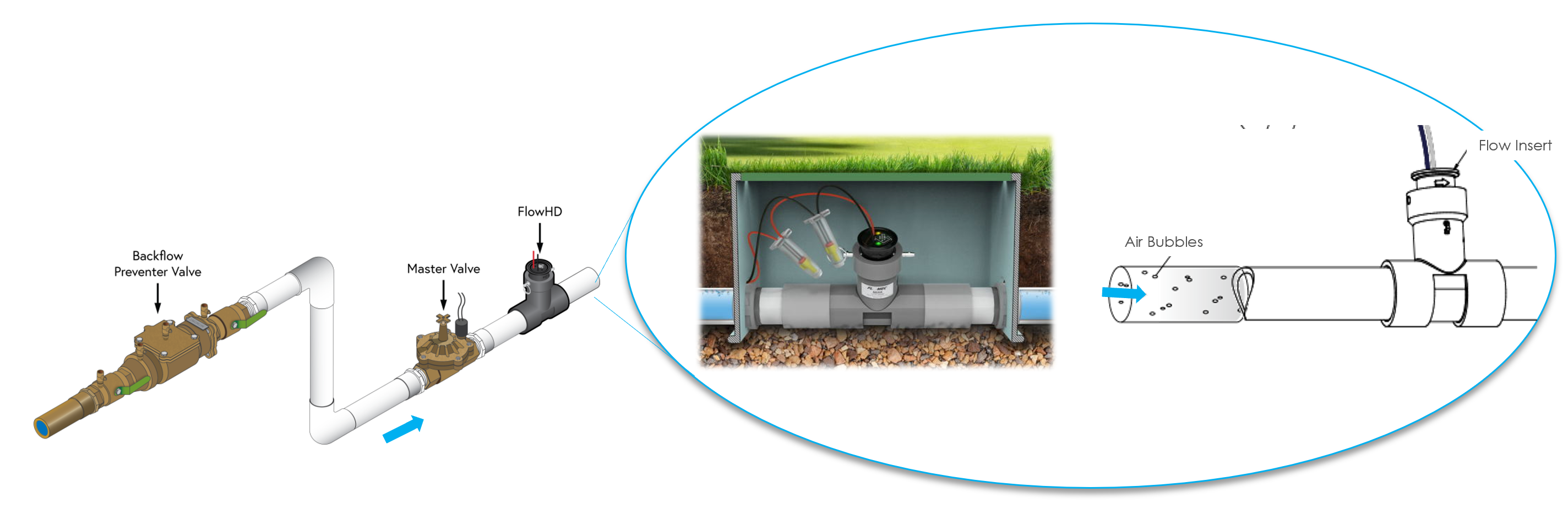

There have been instances when a flow sensor is detecting higher flow than expected, such as detecting flow when watering is unscheduled or the master valve is shut off. So far, these 'phantom flow' events have only occurred with controllers connected to FlowHD Plastic ultrasonic flow sensors. Although there are many environmental factors that could trigger phantom flow (see 'causes' below), FlowHD-P phantom is typically caused by air bubbles trapped near the transducer of the flow sensor - called 'entrained air' - which the sensor incorrectly interprets as water. The trapped air bubbles change the sensor's timing of the pulse readings, leading the sensor to calculate or 'believe' there is a very high rate of flow.

There have been instances when a flow sensor is detecting higher flow than expected, such as detecting flow when watering is unscheduled or the master valve is shut off. So far, these 'phantom flow' events have only occurred with controllers connected to FlowHD Plastic ultrasonic flow sensors. Although there are many environmental factors that could trigger phantom flow (see 'causes' below), FlowHD-P phantom is typically caused by air bubbles trapped near the transducer of the flow sensor - called 'entrained air' - which the sensor incorrectly interprets as water. The trapped air bubbles change the sensor's timing of the pulse readings, leading the sensor to calculate or 'believe' there is a very high rate of flow.

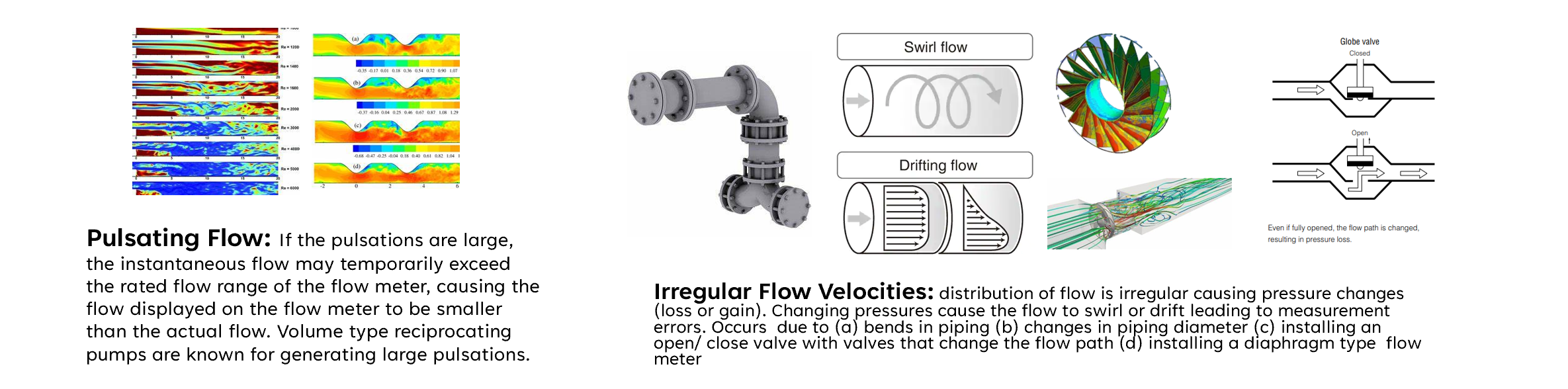

Causes of Incorrect Flow Data

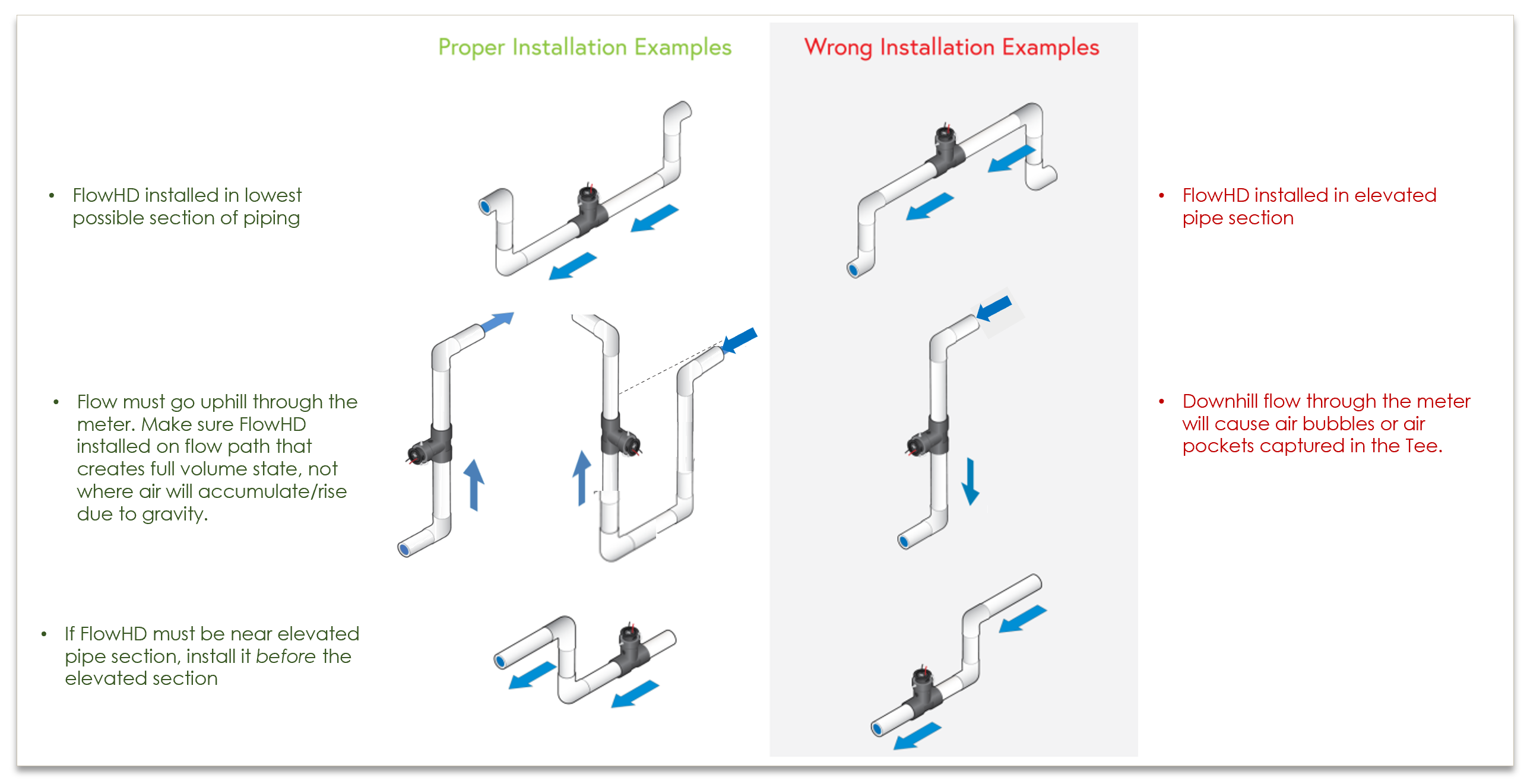

When we encounter an issue with phantom flow readings - the sensor is reading flow when there isn't any - we should address possible air pockets/bubbles being the cause. Installing the sensor at a slight angle, and proper elevation/distance, can help with this issue but may not resolve it based on the sensor size.

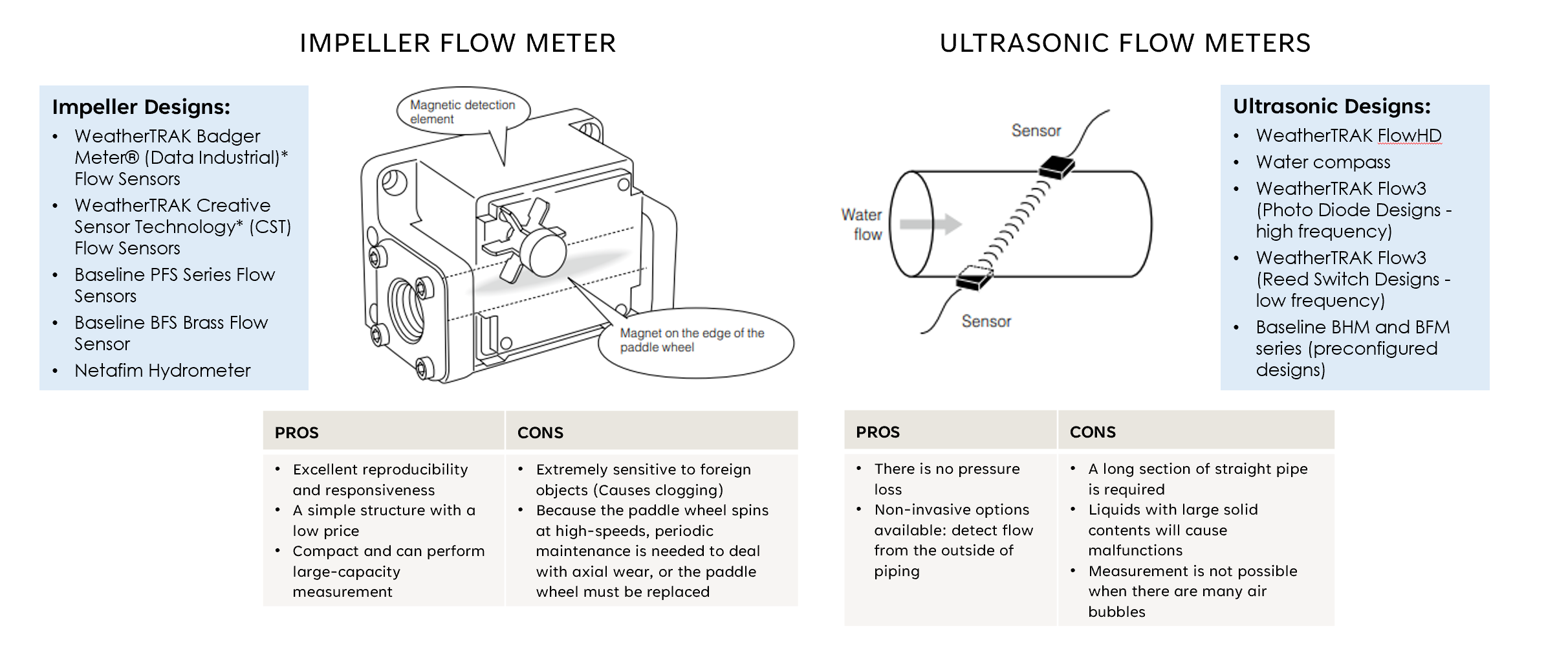

Hydropoint Flow Sensor Types and vulnerabilities of meter

Other types of flow meters and background to the issue can be found in: Keyence Technical Guidebook

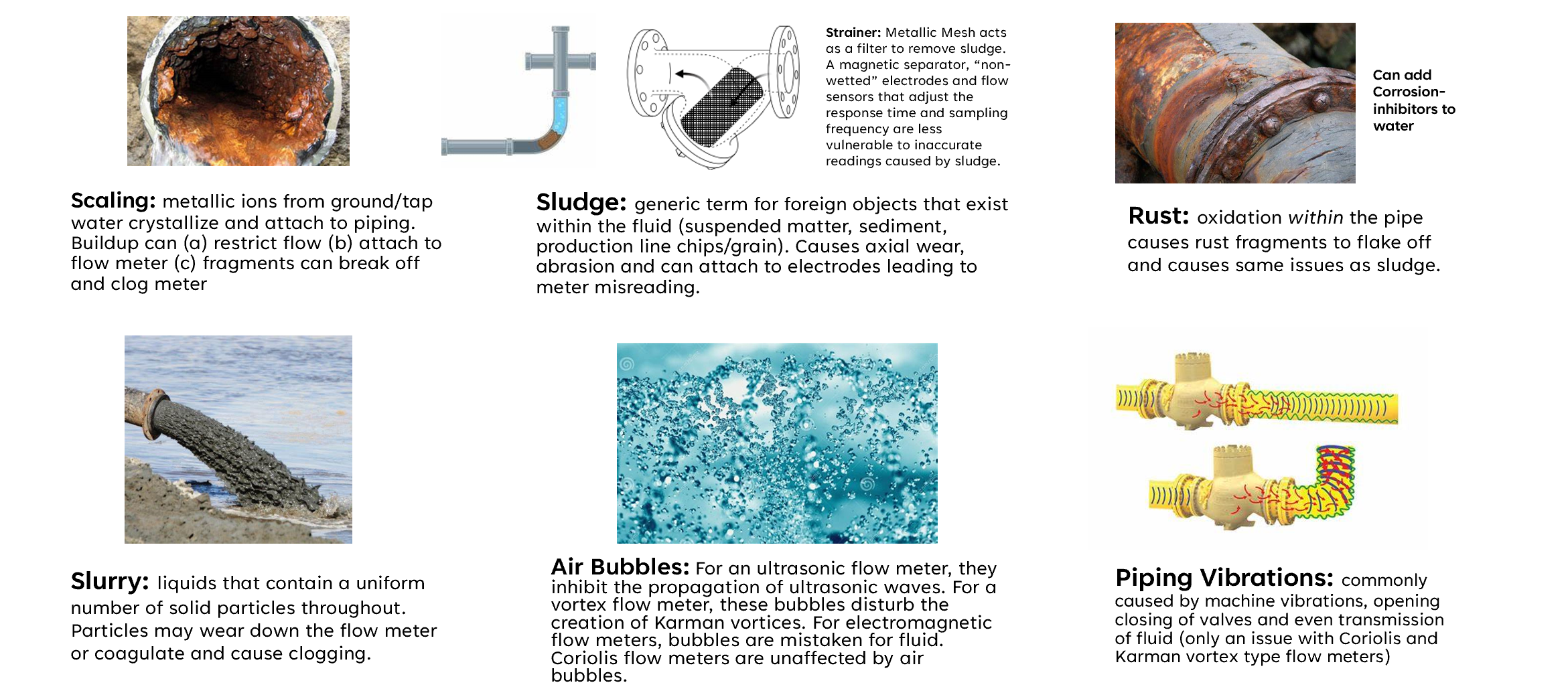

DeleteCertain factors will increase the noise interference from entrained air, such as piping systems that undergo temperature or pressure changes, water impurities, water velocity and vibration in pipes (in industrial applications). The turbulence generated by these conditions cause the amount of air bubbles present to increase.

There are two primary scenarios when phantom flow occurs:

- Scenario #1: When irrigation is complete and the mainline, previously full for the scheduled irrigation, slowly empties. As the station valve drains, or other instances when the valve is closing slowly, the air entering the line starts to find its way to the highest point in the mainline.

-

Scenario #2: There is not sufficient flow or pressure in the mainline to purge air bubbles. This is more common with drip irrigation, when fluid velocity is reduced to a point that the air collecting in the line cannot be purged properly causing interference with the sensor's operation.

If you have experienced this issue, what can you do?

1. Move or angle the ultrasonic sensor away from the location of air pockets where they naturally rise and can collect at the top.

The angle of the T junction plays a crucial role in preventing phantom flow issues. Ensure that the flow sensor is installed at a 45° angle, relative to the ground. This angle is especially important for 1" pipes, which can create phantom flow issues when installed at an improper angle. While the angle does not need to be exact, ensure it is as close to 45° as possible. If you are unsure if the angle is correct, consider taking a photo using a smartphone as a reference.

%20(2).png)

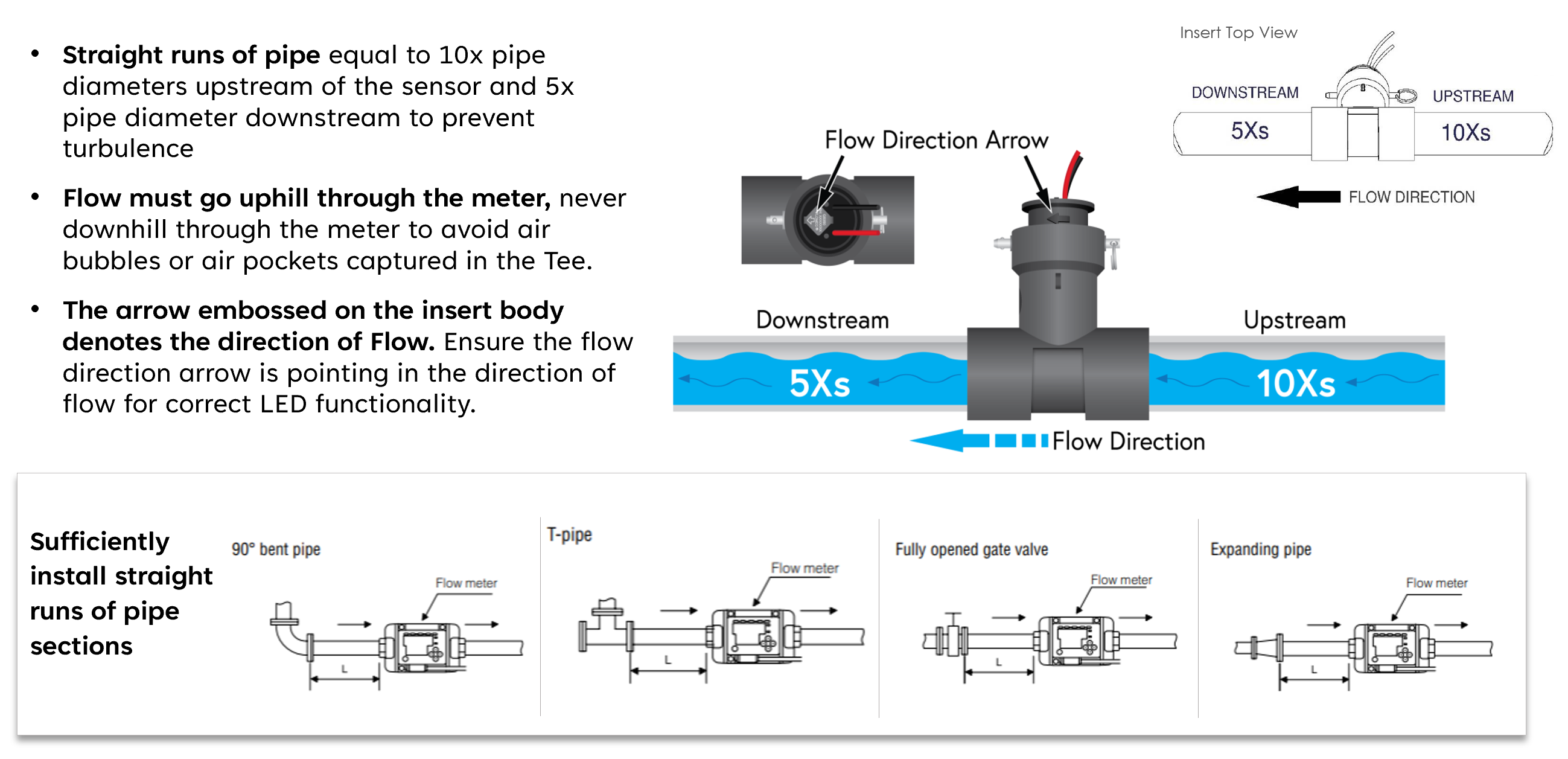

2. Ensure the FlowHD is not in a pipe section that will create noise interference from for the ultrasonic sensor. Particular irrigation configurations can enable or exacerbate this issue. The sensor should be installed at the lowest possible point on the mainline. How much pressure is in the plumbing while irrigating can cause air pockets/bubbles. This is why it is recommended to have the appropriately sized lines and pressure, and to ensure the device is installed to specifications.

Source: FlowHD Plastic Installation Manual

3. Purchase a new FlowHD Plastic insert to ensure your sensor has the most up to date firmware.

-

When the FlowHD Plastic was initially released in 2019, the device was more susceptible to phantom flow events. A firmware update released in January 2020 significantly reduced the sensor's likelihood of malfunctions from air bubbles.

- FlowHD Plastic inserts with the latest firmware in it will have a serial number of 0520xxxx to 5220xxxx or xx21xxxx or xx22xxxx.

-

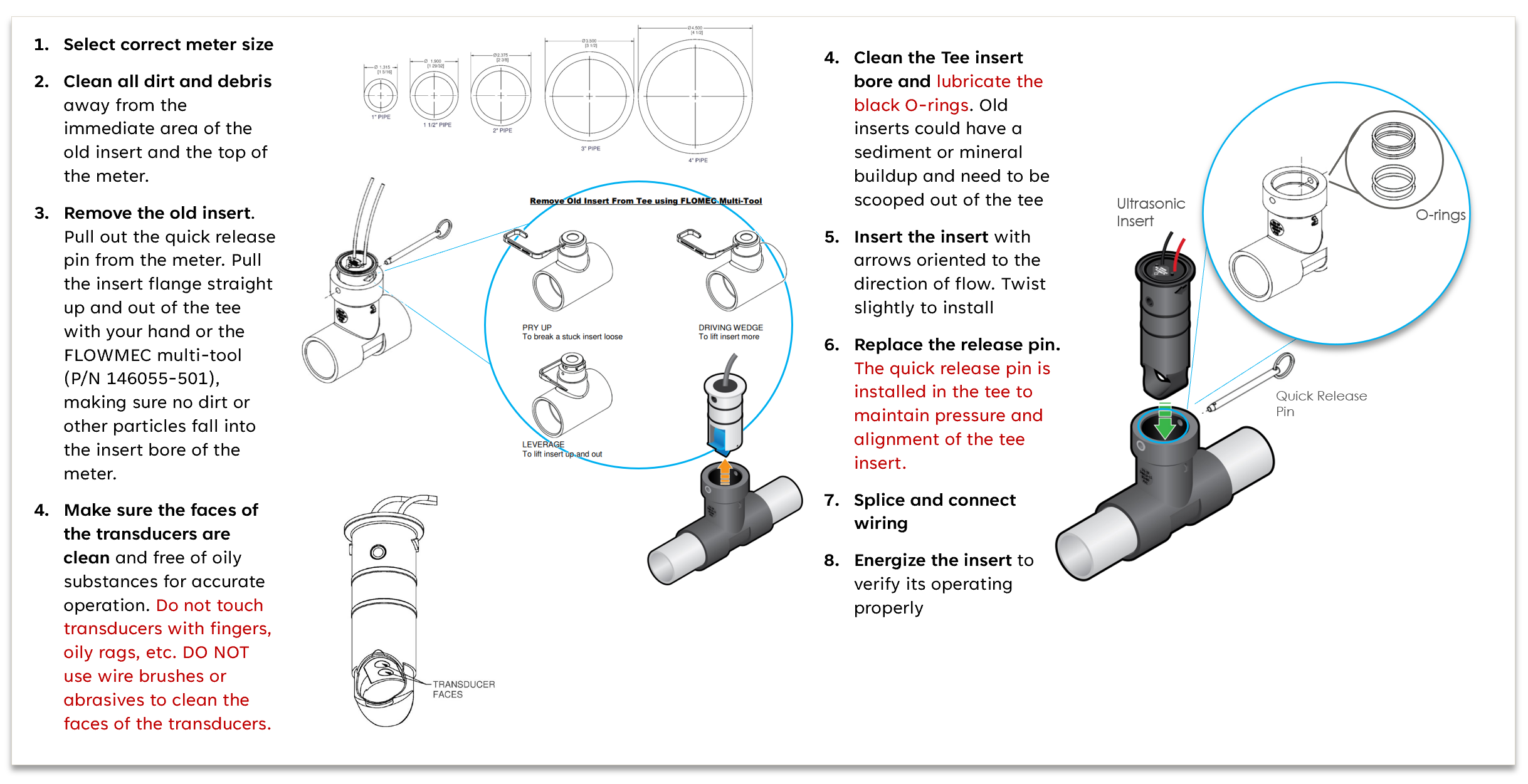

How to Replace

- If it's within its warranty term (3 years) and you are able validate that you are experiencing a phantom flow issue (e.g. backflow turned off and still seeing flow), contact Support and we can create an RMA for the device and send a replacement at no cost.

- If it's outside of the warranty term or you just want the latest flow sensor you can purchase a new insert with your local distributor. Order SKU #: WTFLOWHD-P-INS

Insert Replacement Best Practices

Go to FlowMec QS200 Ultrasonic Flowmeter user manual for more details.

Delete4. Install an air-relief or other auto-drain valves, such as drip emitters, into the hydraulic system to help allow air to escape from the structure. Emitters have flexible diaphragms that are pressure-compensating (pressure modulating), less susceptible to clogging, and help regulate water flow by flushing particles out. Drip emitters are especially useful for turbulent flow systems. We have seen customers have success with many different air-relief valve manufacturers. Kinectic air has been recommended many times link.

Frequently Asked Questions:

Can I modify to correct my phantom flow data for reporting purposes?

- No, not on the user's end. Engineering can go modify the data on your behalf. Please send an email to customer support with (a) data suspected to be phantom flow (watering schedules, recorded flow, issue flow sensor) to Customer Support and we will resolve the issue