The purpose of the FlowStation Configuration Test is to help educate users on what they are configuring and why. Further, the inspector will help users to better understand the features available to them. The FlowStation Configuration Test will run 18 unique tests across the configuration to help locate potential issues that could affect irrigation.

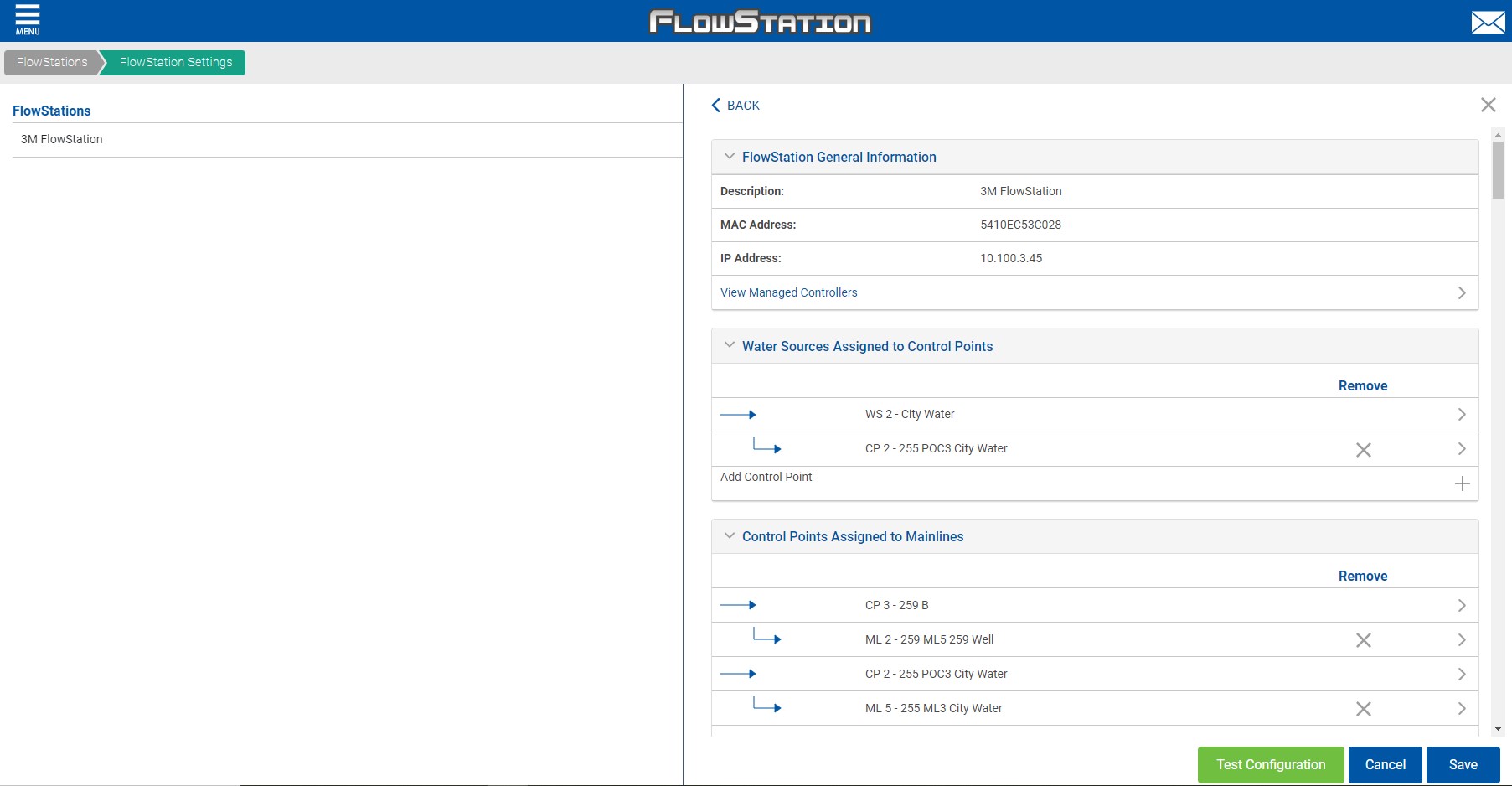

Navigation

- Log into AppManager

- Go to FlowStation App

- Select FlowStation

- Select Edit configuration

- Select “Test Configuration” button

- New slide-out menu appears with test results for the user to review

- The user can retest as needed

Test Results Overview

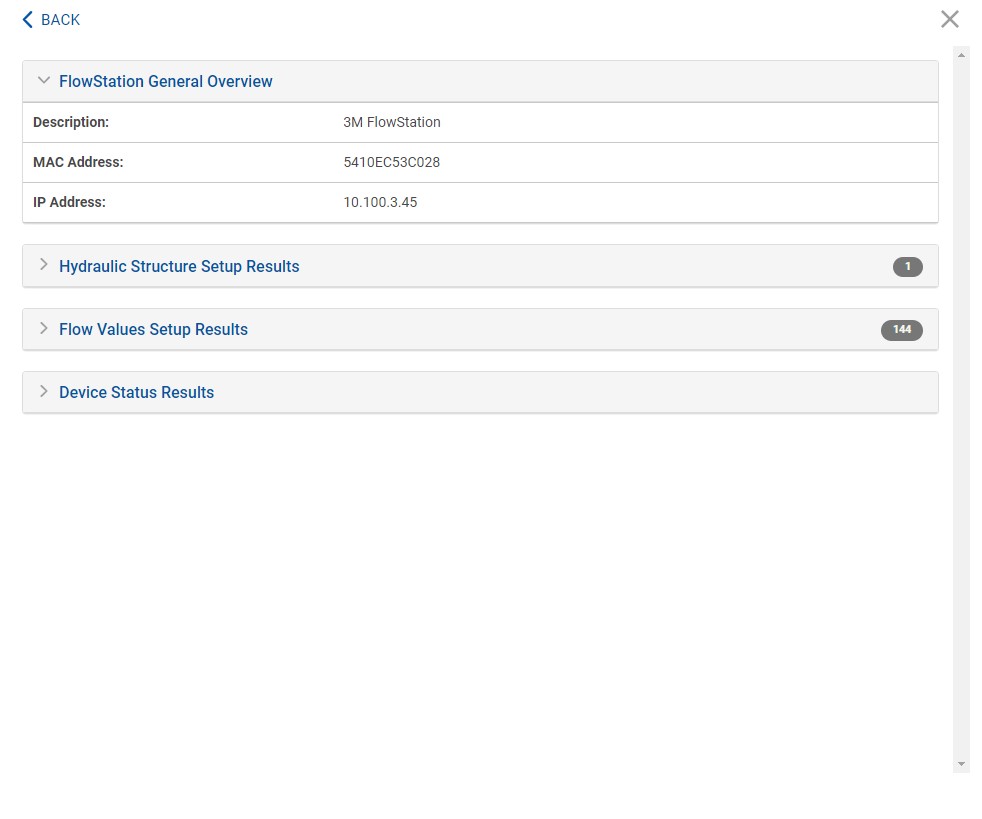

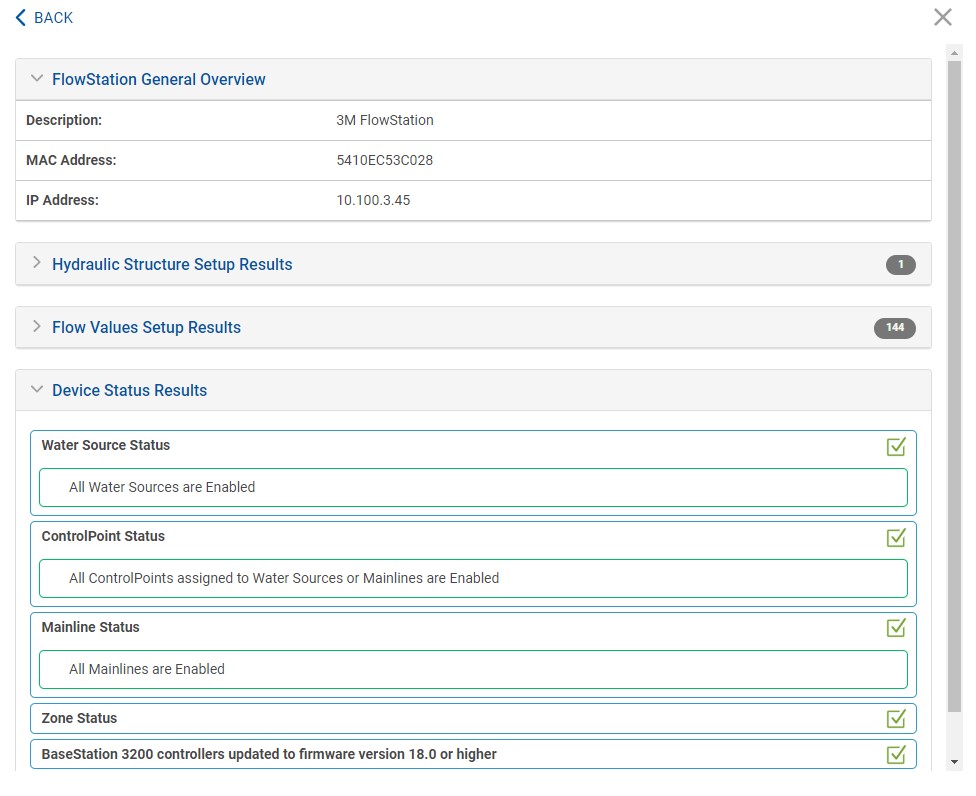

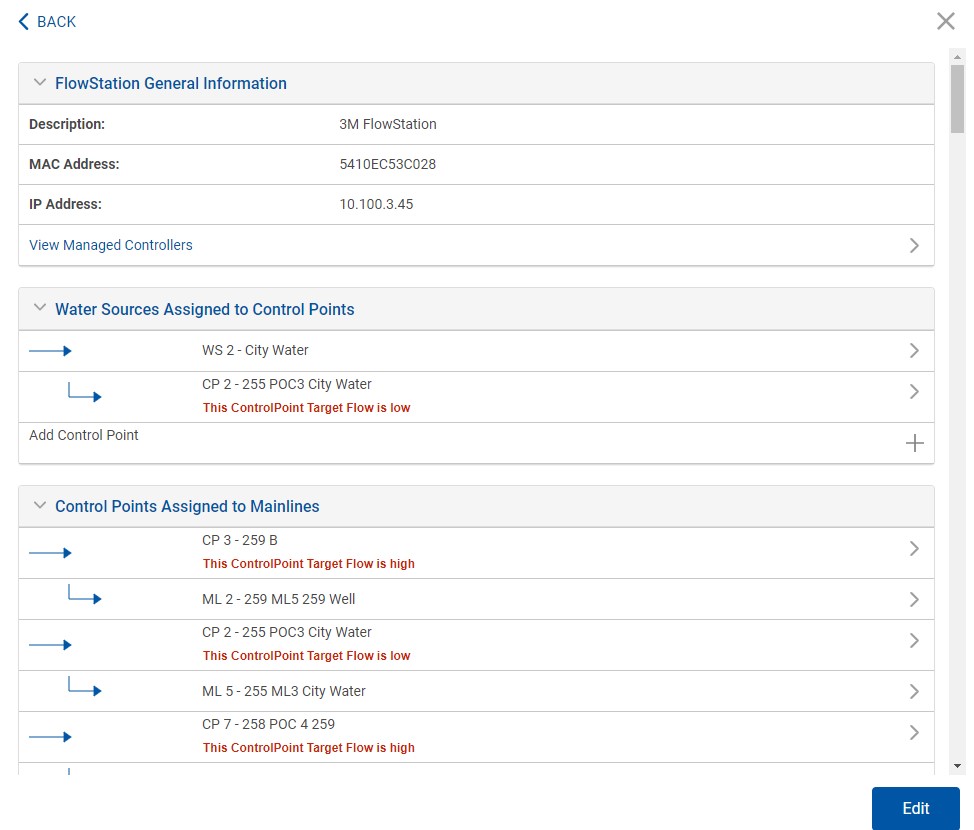

When a user runs the “Test Configuration” process, a new slide out menu will appear. They will first see the FlowStation General Overview. This is the same data as what is on the configuration page to ensure the user is oriented to the correct FlowStation.

The test results are organized by three primary categories:

- Hydraulic Structure Setup Results

- Flow Values Setup Results

- Device Status Setup Results

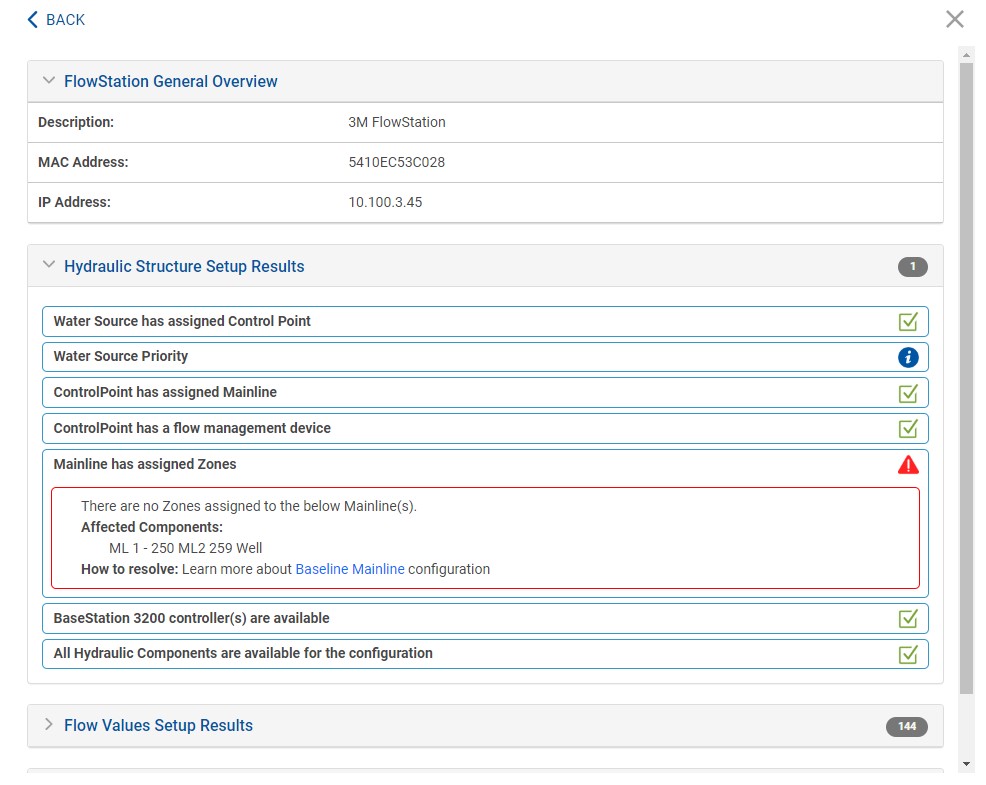

Within each category the test engine will display various tests that will show the user where their configuration is setup correctly or not. The user will see “alert” notifications for parts of their configuration that might have issues. The user can see how many issues are within each category by quickly referencing the value on the right side of each header bar.

The test engine will be display the results accordingly:

- Information icon = reference information only, not a pass or fail test

- Failed test = appears in red text with a description of what is incorrect and a link to the knowledgebase for more information about how they can resolve the issue. The results will also list “affected components” to show what specific Water Source, ControlPoint, Mainline, or Zone has the issue.

- Passed test = appears in green text with a “success message” to indicate there aren't likely issues

The test results are only for reference and display. The user can still save the configuration even with potential issues present.

Hydraulic Structure Setup Results

The tests for this section look for issues with how the user has configured their hydraulic components.

Tests and Messages:

- Water Source has assigned Control Point

- Success message: All configured Water Source(s) have a ControlPoint assigned

- If no, a red alert icon appears with the following message:

- There is no ControlPoint assigned to this Water Source

- ControlPoint has assigned Mainline

- Success message: All configured ControlPoint(s) have a Mainline assigned

- If no, a red alert icon appears with the following message:

- There is no Mainline assigned to this ControlPoint

- ControlPoint has a flow management device

- Success message: All configured ControlPoint(s) have a Flow Management device

- If no, a red alert icon appears with the following message:

- A flow management device is not required but is strongly recommended for optimal flow management performance

- Mainline has assigned Zones

- Success message: All configured Mainline(s) have a Zone assigned

- If no, a red alert icon appears with the following message:

- There are no Zones assigned to this ControlPoint

- BaseStation 3200 controller(s) are available

- Failure message: “Controller Description - Serial Number” is no longer part of the FlowStation Group. The controller may have been removed or it is offline. The Hydraulic Components associated with this controller are no longer available.

- Success message: “The BaseStation 3200 controller(s) with configured Hydraulic Components are available.”

- All Hydraulic Components are available for the configuration

- Failure message: The following Hydraulic Components are not available.

- Success message: “All Hydraulic Components are available for the configuration.”

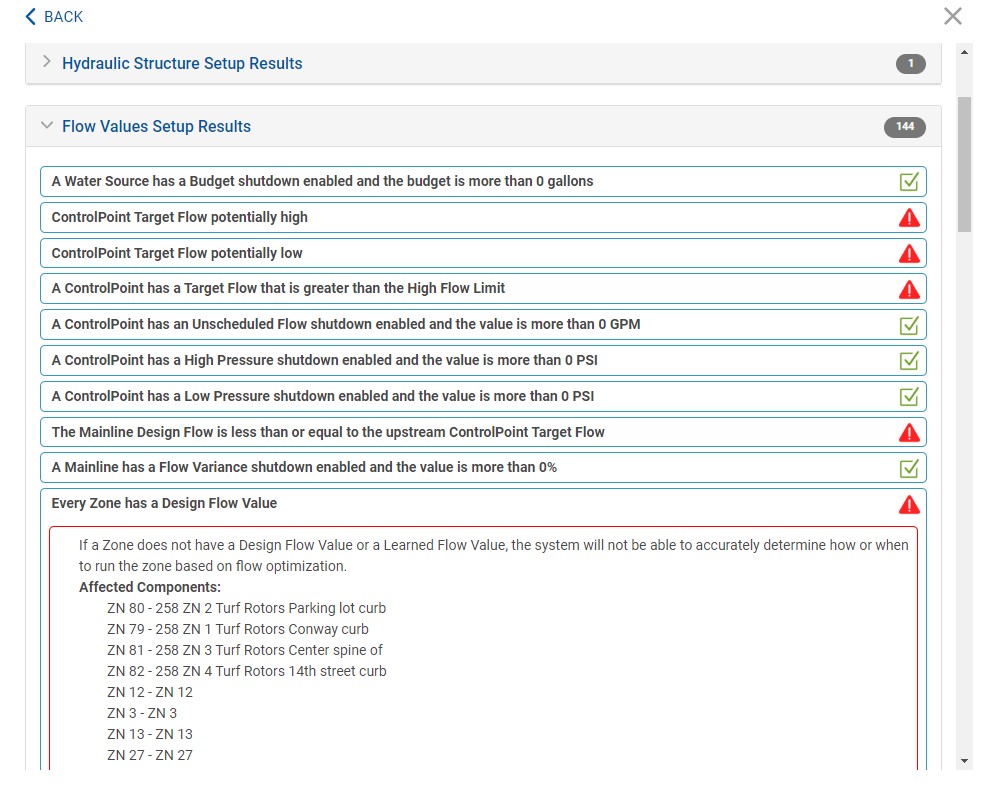

Flow Values Setup Results

This part of the test engine shows the user if there are potential issues with how they configured the flow values for their system.

Test results and messages:

- A Water Source has a Budget shutdown enabled and the budget is more than 0 gallons

- Success message: There is a Monthly Budget shutdown enabled for Water Source: “input description.” The allowed budget for the Water Source is more than 0 gallons.

- Failure message: There is a Monthly Budget shutdown enabled for this Water Source: “input description.” The allowed budget is 0 gallons which means the Water Source will not allocate water after 1 gallon has been measured.

- A ControlPoint has a Target Flow that is greater than the High Flow Limit

- Success message: There is a High Flow Limit for ControlPoint: “input description” that is greater than the Target Flow. This is a supported configuration.

- Failure message: There is a Target Flow for ControlPoint: “input description” that is greater than the High Flow Limit. This will cause the system to generate an alert every time the system runs.

- A ControlPoint has an Unscheduled Flow shutdown enabled and the value is more than 0 GPM

- Success message: There is an Unscheduled Flow shutdown enabled for ControlPoint: “input description.” The value for Unscheduled Flow is greater than 0 GPM which is a supported configuration.

- Failure message: There is an Unscheduled Flow shutdown enabled for ControlPoint: “input description.” The value for Unscheduled Flow is 0 which means this ControlPoint will shutdown as soon as 1 GPM of Unexpected Flow is measured.

- A ControlPoint has a High Pressure shutdown enabled and the value is more than 0 PSI

- Success message: There is a High Pressure shutdown enabled for ControlPoint: “input description.” The value for the High Pressure shutdown is greater than 0 PSI which is a supported configuration.

- Failure message: There is a High Pressure shutdown enabled for ControlPoint: “input description.” The value for the High Pressure shutdown is 0 PSI which means this ControlPoint will shutdown as soon as 1 PSI is measured during system operation.

- A ControlPoint has a Low Pressure shutdown enabled and the value is more than 0 PSI

- Success message: There is a Low Pressure shutdown enabled for ControlPoint: “input description.” The value for the Low Pressure shutdown is greater than 0 PSI which is a supported configuration.

- Failure message: There is a Low Pressure shutdown enabled for ControlPoint: “input description.” The value for the Low Pressure shutdown is 0 PSI which means this ControlPoint will not shutdown during system operation.

- Every Zone has a Design Flow Value

- Success message: All Zones have a Design Flow Value

- Failure message: The following zones do not have a Design Flow Value which could cause unexpected system behaviors:

- Zones with a Design Flow greater than the Mainline Design Flow

- Success message: There are no Zones with Design Flow value greater than the Mainline Design flow.

- Failure message: The following Zones have a Design Flow value greater than the Mainline.

Device Status Results

This is where the user can see the status of their devices which could impact system behavior.

Tests and messages:

- Water Source Status

- Success message: All Water Sources are Enabled

- Failure message: There are disabled Water Source(s). If a Water Source is disabled the system will not irrigate.

- Affected Components:

- ControlPoint Status

- Success message: All ControlPoints assigned to Water Sources or Mainlines are Enabled

- Failure message: There are disabled ControlPoint(s). If a ControlPoint is disabled the system behavior will be affected.

- Affected Components:

- Mainline Status

- Success message: All Mainlines are Enabled

- Failure message: There are disabled Mainlines(s). If a Mainline is disabled the system behavior will be affected.

- Affected Components:

- Zone Status

- Success message: All Zones are Enabled

- Failure message: There are disabled Zones(s). If a Zone is disabled the system behavior will be affected.

- Affected Components:

- BaseStation 3200 controllers updated to firmware version 18.0 or higher

- Success message: All BaseStation 3200 controllers are updated to firmware version 18.0 or higher

- Failure message: There BaseStation 3200 controllers using outdated firmware. Controllers using outdated firmware could affect system behavior.

- How to Resolve: Learn how to update your Controller firmware

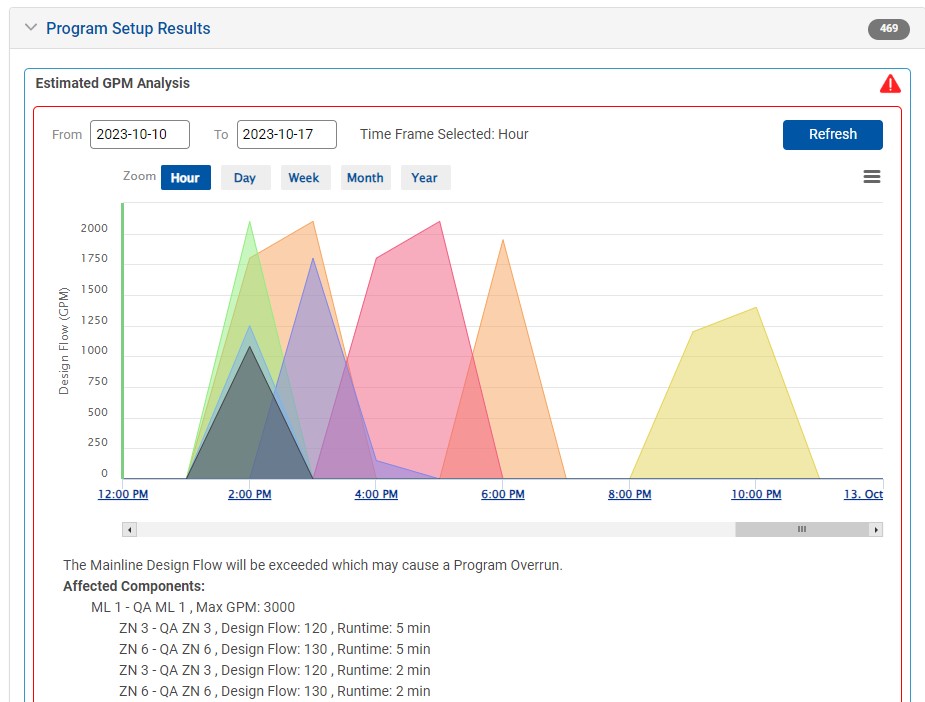

Program Setup Results

This is where the user can see the outcome for their programming model which could impact system behavior. This is where we’ll display information for what programs are expected to run and when and how much max GPM will be required. This establishes if there are probable conflicts that will result in a program overrun.

Demand and duration is based on:

- Program start time

- We can reference the “Next Start” time from the controller and therefor when demand will take place for that mainline in the future

- Program water window could be used to show if the water window fits within a 24 hour period.

- Estimated program run time

- The program runtime might be less than the program water window which gives us another data point for a time-bound duration window

- Number of zones total in the program

- Design Flow for each Zone

- Zone concurrency setup

- Mainline Design Flow

The Program Setup Results window will display test results for each mainline with a zone assigned.

The user can select a date for which to display the expected flow.

If a date is selected and there are no flow values to populate we will display a message to the user that no data is available.

The Program Setup Results will start with the most upstream mainline at the top and then each mainline in the hydraulic configuration will have test results displayed.

For the graph itself, the programs with the highest priority level will be at the bottom and then stack upward with the lowest priority at the top.

We will be able to visually differentiate the different program priorities

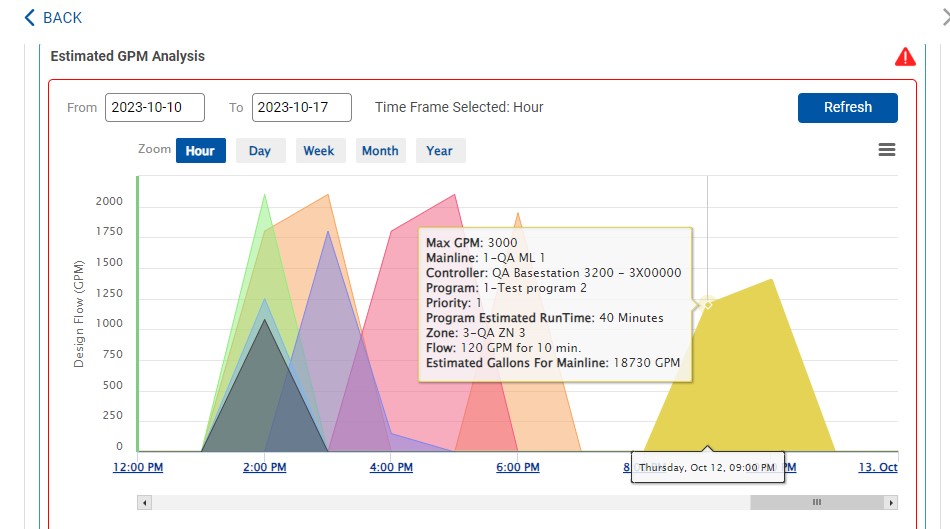

When a user hovers over a program, a conversation box will appear that includes contextual information about that program including:

- Mainline Max GPM value

- Mainline Name

- Controller Name

- Program Name

- Program Priority

- Estimated Program Runtime

- Zones in the Program

- Estimated Max GPM flow required for Program

- Total estimated flow usage for Program

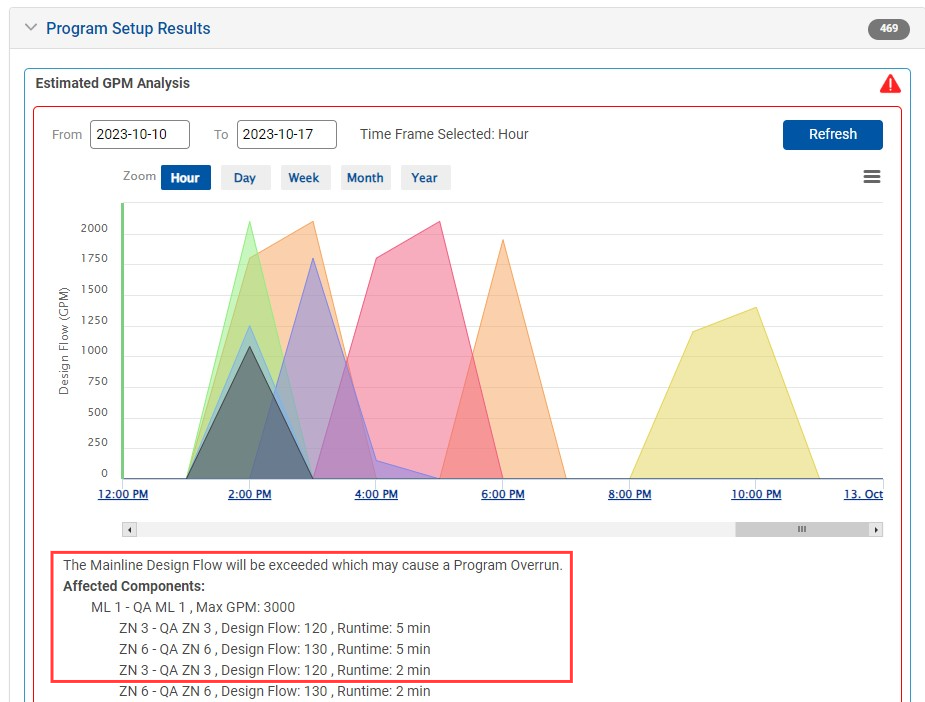

If the total estimated GPM required for a program or multiple programs exceeds the mainline threshold, the Program Setup Results will flag that mainline and list the programs and zones that may be affected by a program overrun.

When you exist the test results page and go back to the Setup/Configuration page, the hydraulic components that have an issue associated with them will be highlighted on the page. This is to help the user understand what they may need to do more work to resolve potential issues.

FAQs

-

I see that somethings did not pass a test, will my system not run?

- The FlowStation Configuration Test does not affect irrigation. It is intended to show you areas where you can improve your system performance and to ensure the system has the basic requirements for operation.

-

If I have open issues in “red” on the configuration page, will it still allow me to save my work?

- Yes. The items highlighted in red text on the configuration page are there to show you where the FlowStation Configuration Test has found an issue. You can save your work and come back later to resolve potential issues.

-

The FlowStation test failed one of my Mainlines for not having a zone even though it's not supposed to have a zone.

- The FlowStation will support configurations that have a Mainline to Mainline assignment. We understand it's possible to have a mainline that doesn't have zones. If this is true for your site, you can ignore this test result. The purpose for this test is to ensure the minimal configuration requirements are met.

-

The FlowStation test indicates that there might be issues with my flow values but it doesn't tell what values I should use.

- Because every site is different, the test can't know what flow values should be. We are working on a new feature that will allow users to input additional data that will help use provide suggested or recommended values.

-

Does the FlowStation test work on Water Sources, ControlPoints, Mainlines, or Zones that are not assigned to the FlowStation?

- No. If a 3200 has hydraulic components not assigned to the FlowStation, the FlowStation test will not be able to test those components. We are working on expanding the test interface to include the 3200 and 1000 at a future date.